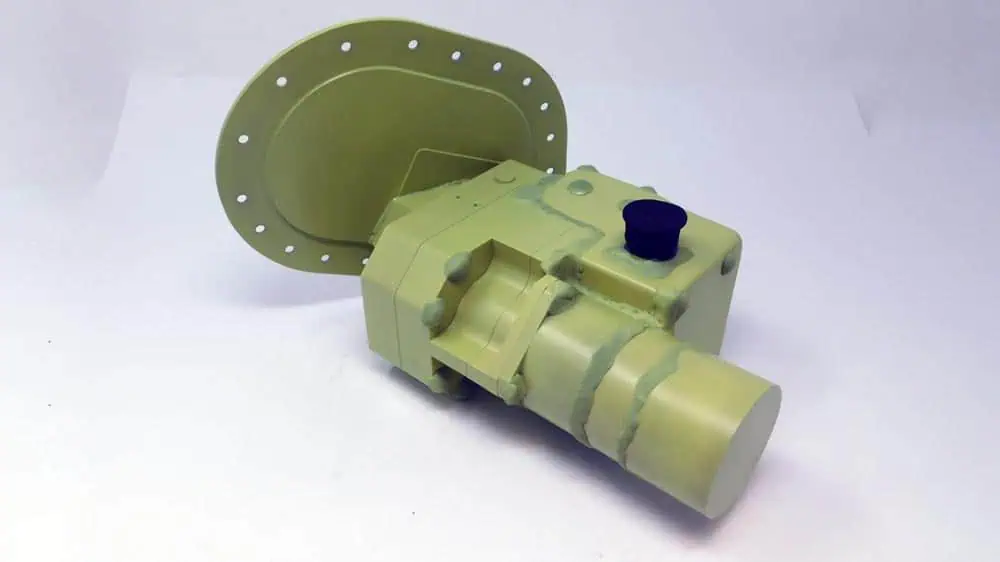

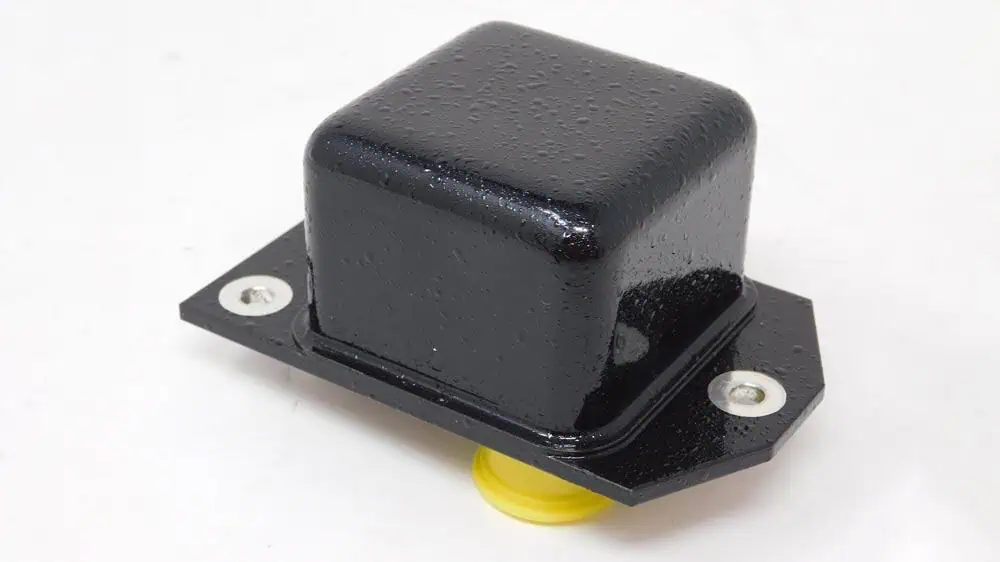

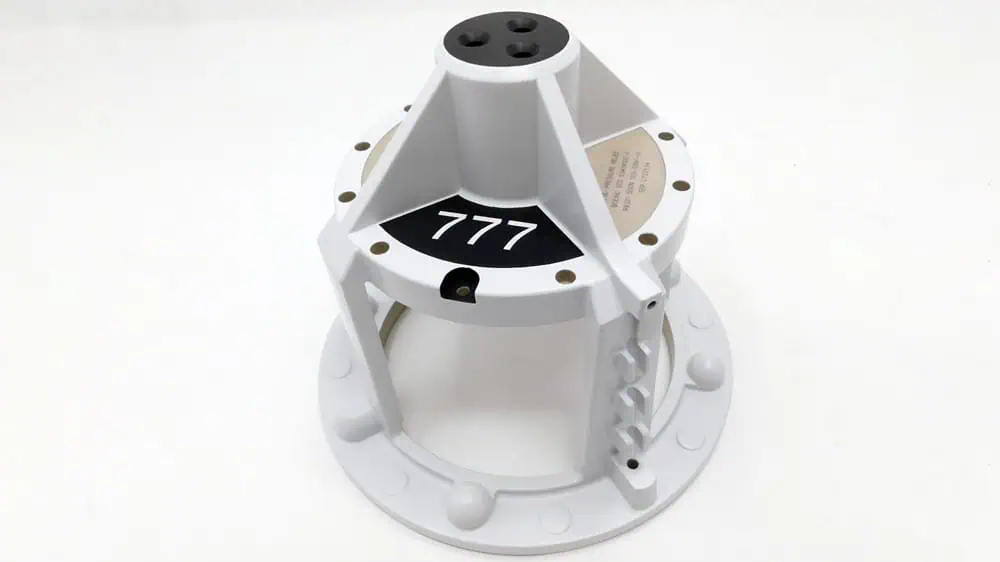

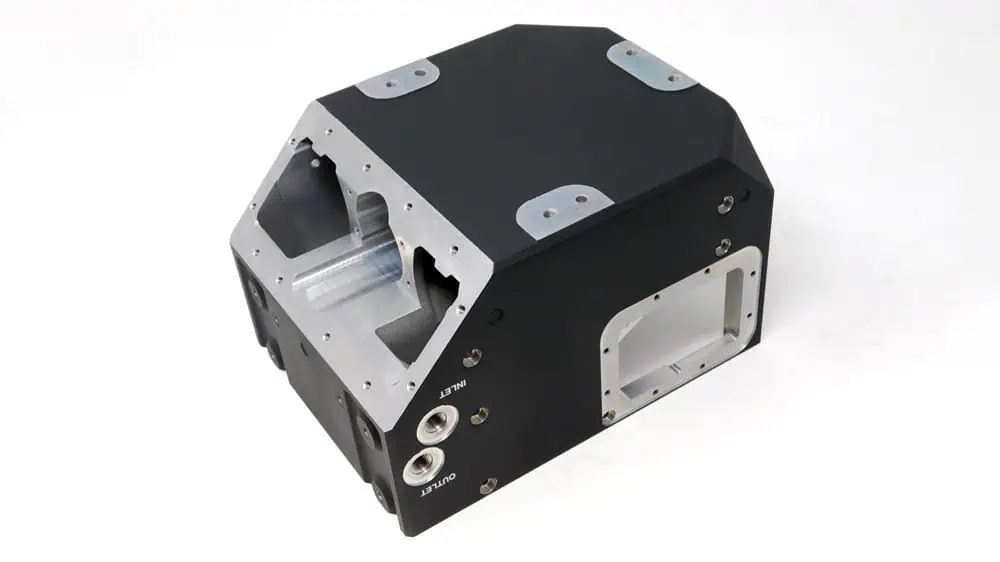

Prime Products specializes in spray painting parts with complex masking and stringent cosmetic requirements.

We design and build most of our spray masks and fixtures in-house. We also stock a wide variety of off-the-shelf plugs and caps.

Our surface prep capabilities include sand blasting, liquid honing, washing, ultrasonic cleaning, solvent cleaning, and plasma jet treating.

We have four ultra-clean spray rooms with a total of 16 spray booths to apply the paint, and we have 9 ovens (4 batch, 5 walk-in) for accelerated curing.

We can test each lot for thickness, adhesion, color and gloss, and/or solvent resistance, and we perform a 100% visual inspection to ensure compliance with our customer’s workmanship standard or our internal standard.

The tables below list the manufacturers we buy paint from, the military specifications to which these paints are certified, and the military and aerospace OEM specifications that we can comply with.

Paint Manufacturers |

|

|---|---|

| AkzoNobel | Humiseal |

| Alsa | Inkcups Now |

| Avian | Intrepid |

| Axalta | Klinger |

| Cardinal | Mankiewicz |

| Chemsol | Momentive |

| DayGlo | PPG |

| Dupont | Randolph |

| Eastern Chem-Lac | Seagrave |

| Enthone | Sherwin-Williams |

| Exxene | Solvay |

| Genesis | Spectrum Coatings |

| Hentzen | Spraylat |

| WLS Coatings | Trans-Chem |

Mil-Spec Primers and Paints |

|

|---|---|

| A-A-56032 | MIL-PRF-22750 |

| DOD-P-15328 | MIL-PRF-23377 |

| MIL-DTL-15090 | MIL-PRF-24635 |

| MIL-DTL-24441 | MIL-PRF-26915 |

| MIL-DTL-53022 | MIL-PRF-81352 |

| MIL-DTL-53039 | MIL-PRF-85285 |

| MIL-DTL-64159 | MIL-PRF-85582 |

| MIL-I-46058 | TT-P-1757 |

Military and Aerospace OEM Specifications |

|

|---|---|

| Astronautics ES53 | DOD MIL-DTL-14072 |

| Boeing BAC5325 for BMS10-103 GR E | DOD MIL-DTL-53072 |

| Boeing BAC5639 for BMS10-21 TY III | DOD MIL-STD-171 |

| Boeing BAC5837 for 825X466 | DOD MIS-10012 |

| Boeing BAC5845 for BMS10-60 TY II | GE Aviation Systems SD1037 |

| Boeing DPS4.50-152 | Honeywell 001-00044 |

| Collins Aerospace 255999 | Honeywell HPS1010 |

| Collins Aerospace 580-0165 | Honeywell M4065816 |

| Collins Aerospace 580-0194 | Hoover Electric HE-1-38 |

| Collins Aerospace 580-0328 | Kaiser Aerospace 13008 |

| Collins Aerospace 580-0538 | L3Harris 21412 |

| Collins Aerospace 580-0564 | L3Harris 6003136 |

| Collins Aerospace 580-0709 | Lockheed Martin 79P020007 |

| Collins Aerospace 580-0829 | Naval Sea Systems Command WS 25381 |

| Collins Aerospace 580-0918 | Northrup Grumman PR5-3-1 |

| Collins Aerospace 580-5482 | Northrup Grumman PS83680PA |

| Collins Aerospace 580-5498-001 | Parker P1195 |

| Honeywell 001-00044 | Parker P2299 |

| Honeywell HPS1010 | Parker P2304 |

| Honeywell M4065816 | Tru Simulation + Training 10000-50000 |

| Hoover Electric HE-1-38 | Virgin Galactic VGPSMY3000 |