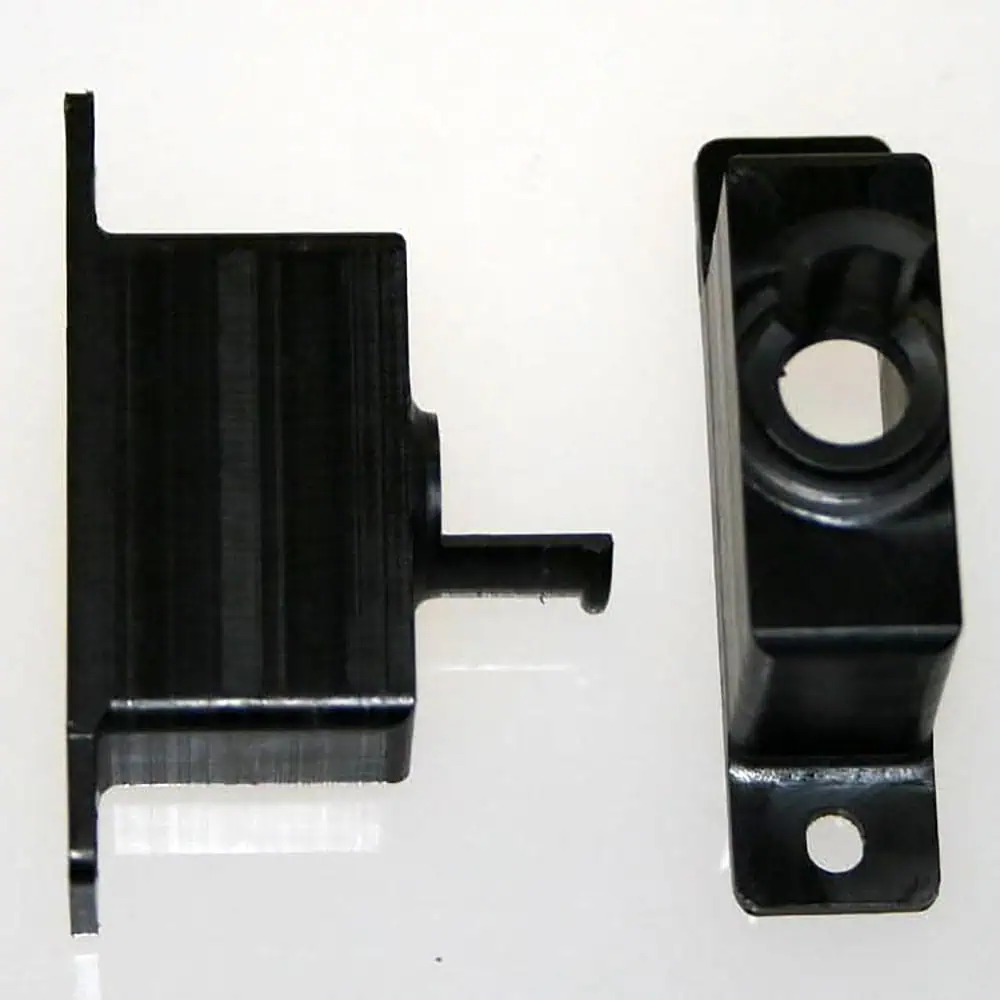

A customer in the aerospace industry asked us to machine this polycarbonate connector piece per their drawing. The customer had designed this part as an injection molded part but transitioned to a machining due to low production volume.

Manufacturing of this item requires the use of our precision CNC machining capabilities. Throughout the manufacturing process, we subject the connector to stringent quality control measures. Prime Products produces approximately 100 per year of this item for an aerospace customer in Phoenix, Arizona.

For more information on the complex fabrication processes and materials used on this product, see the table below or contact us directly.