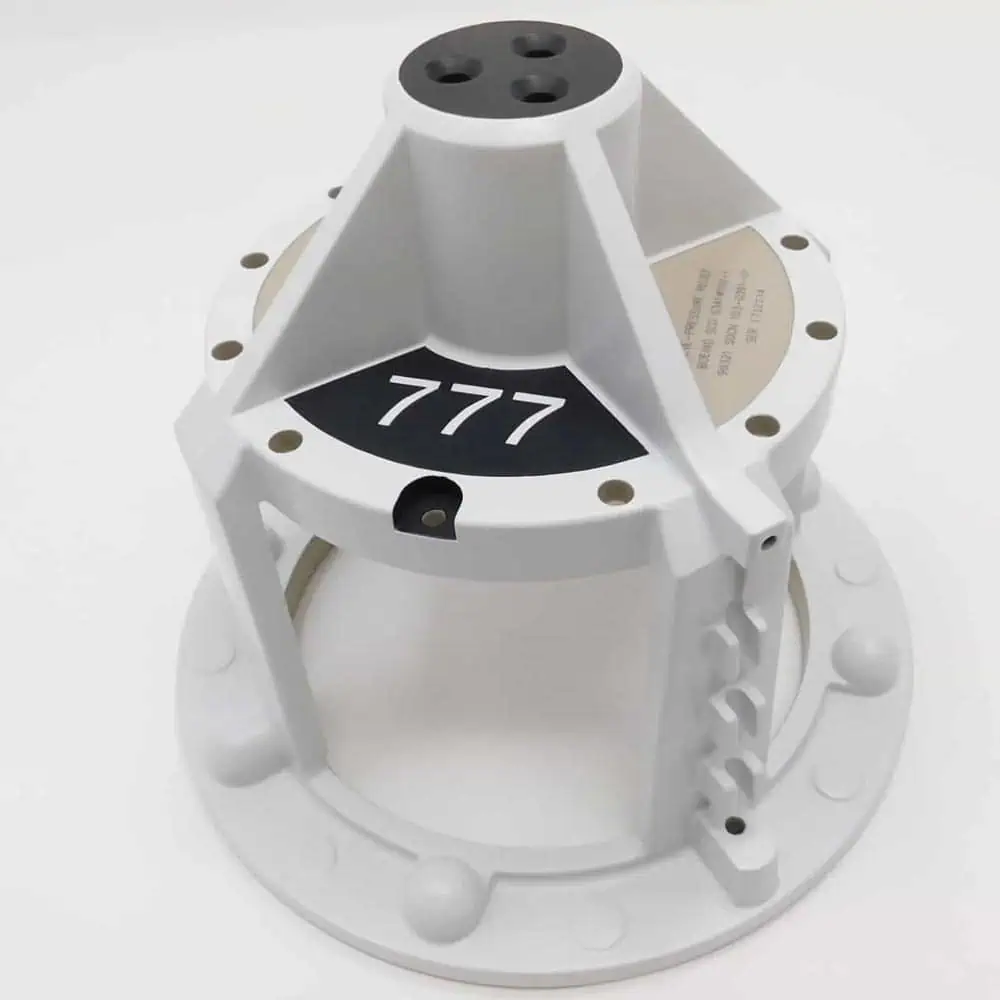

The housing shown here was designed by one of our customers for use in an avionics fuel system. Our customer needed a company to apply the parts marking and three paint finishes using Nadcap certified processing. The customer provides the molded PEEK housing and Prime Products finishes the part according to the drawing and specifications provided.

We etch the ID marking, including serial number and data matrix, onto the part using our laser etching on our Ytterbium fiber laser. Next, we liquid honed the housing to prepare the surfaces that will be painted. We use custom cut decals to mask the part, and meticulously paint the required surfaces with a Boeing paint system. The second coating is conductive and is applied to meet customer requirements for resistivity. Finally, our highly trained staff then inspects every aspect of the finish to ensure our customer’s exacting standards are met before carefully packaging the part for return.

To learn more about this project, see the table below or contact us directly.