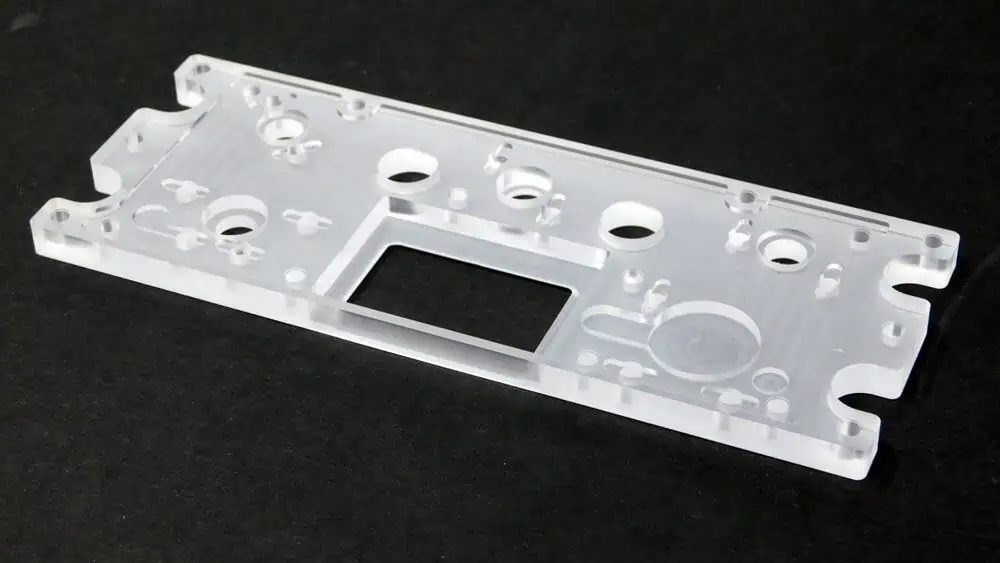

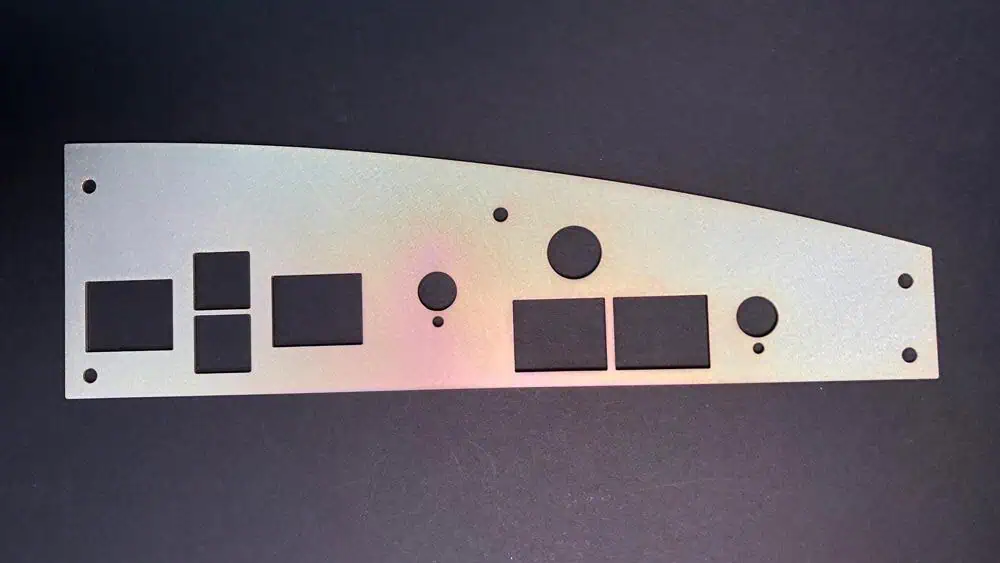

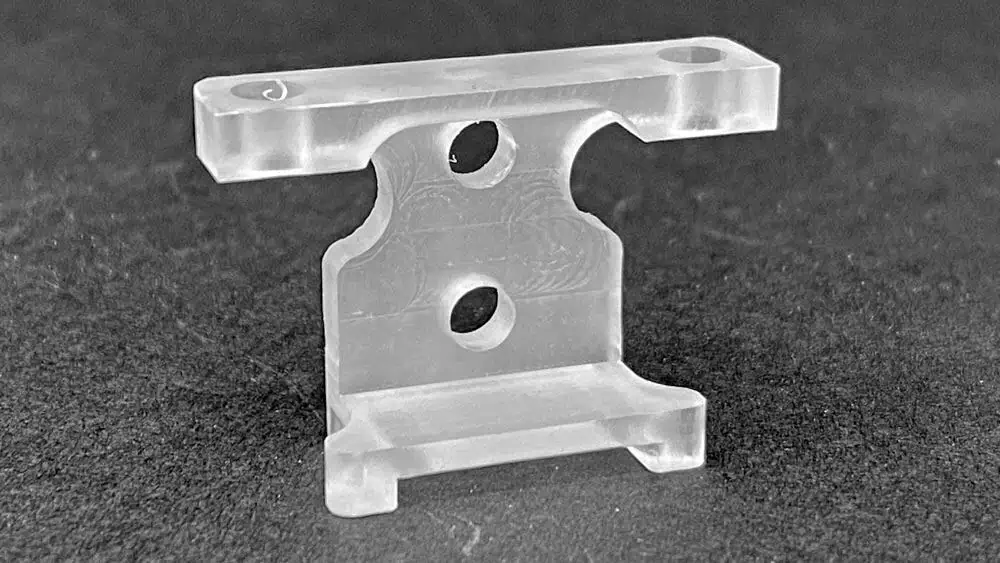

Prime Products specializes in CNC machining parts that are small to mid-size, low to moderate-complexity, and that will be painted or are otherwise cosmetically sensitive. We also use our CNC’s to build holding fixtures and to remove paint precisely and efficiently in lieu of masking.

Our CNC’s are programmed using InventorCAM. Our customers typically provide a solid model, but we can create the model from the drawing if necessary.

We commonly hold tolerances of ± .005” and can hold down to .001” on holes. We have a full array of inspection equipment to ensure tolerances are held, including touch-probe and vision CMM’s.

The table below lists some of the materials that we commonly cut.

Materials |

|

|---|---|

| Acrylic per ASTM D4802 | Homalite H101 |

| Acrylic per L-P-391 | Nylon 6 |

| Acrylic per MIL-PRF-5425 | Nylon 6/6 |

| Aluminum 2024 | Stainless Steel |

| Aluminum 5052 | Teflon (PTGE) |

| APACP22-075-STD (amber polarizer) | TUFFAK GP (polycarbonate) |

| APACP22-075-GL99 (amber polarizer) | UHMW |

| Delrin 100AF (acetal) | Ultem 1000 |

| Delrin 150 (acetal) | |

| FR-4/G-10 | |

| HDPE | |